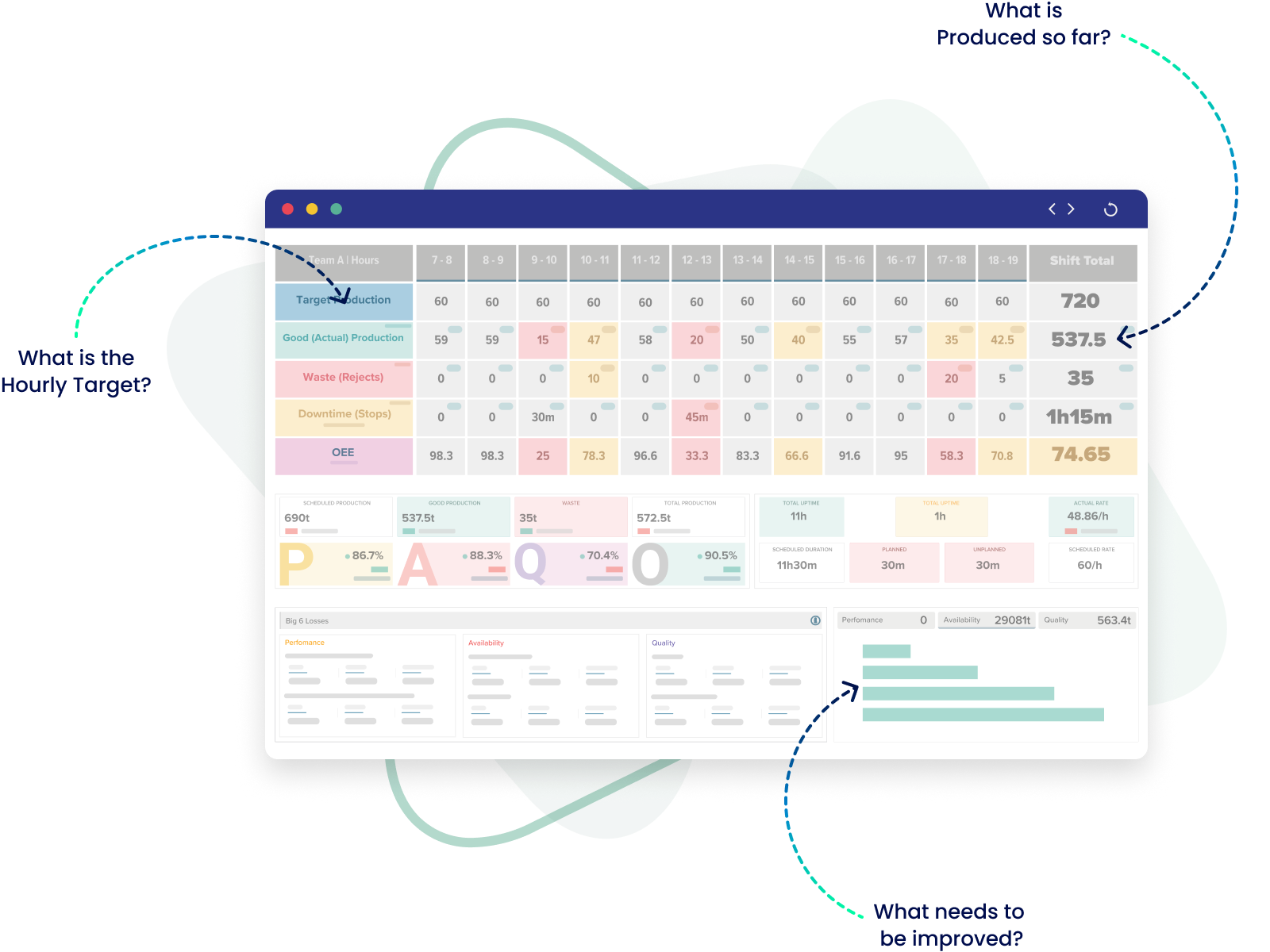

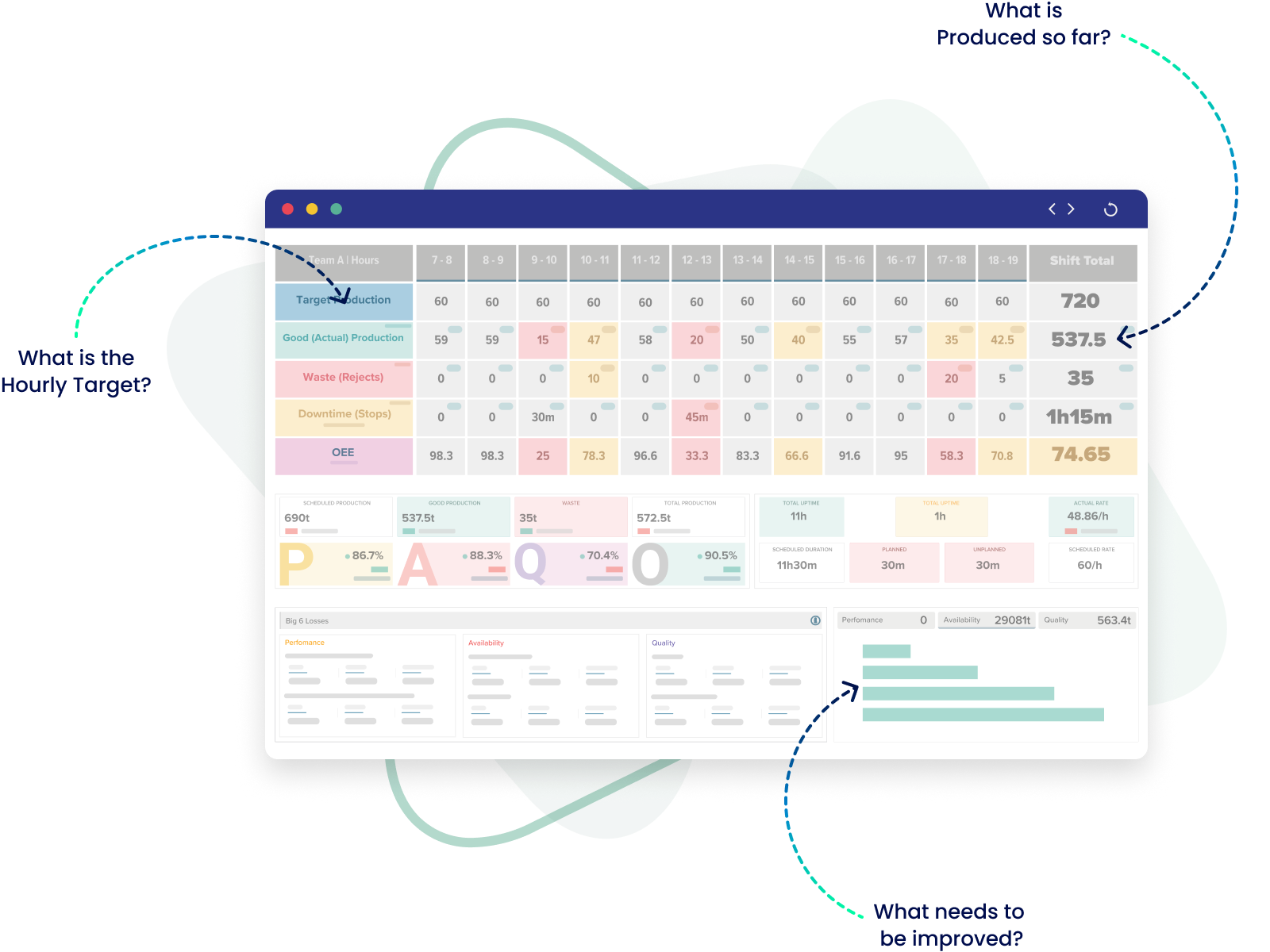

What are Pacing Boards?

Production pacing boards are visual management tools that help track and monitor real-time production data on the shopfloor. They typically display key performance indicators (KPIs) such as machine status, production targets, and actual production output, in an easy-to-read format. The boards are designed to provide real-time visibility into the production process and help teams identify bottlenecks, issues and opportunities for improvement.

What are the Benefits of Pacing Boards?

Production pacing boards provide a number of benefits to manufacturers and production facilities:

- Real-time data tracking: The boards provide real-time visibility into production processes, making it easier to track progress and identify areas for improvement.

- Visual management: The visual format of the boards makes it easier for teams to understand production performance, and quickly identify issues.

- Increased efficiency: The real-time tracking of production data helps teams to identify and eliminate bottlenecks, resulting in improved production efficiency.

- Improved communication: By providing teams with real-time data on production performance, the boards facilitate better communication and collaboration between different departments.

- Increased productivity: By eliminating bottlenecks and improving efficiency, the boards help to increase overall production and boost productivity.

Why Use a Pacing Board for Shop Floor Efficiency?

Pacing boards are a visual way to monitor production, and they help to improve process efficiency. Pacing boards allow you to see the relationship between work in progress (WIP) and capacity utilization, which can be used as an indicator for overall production levels. They also provide information about waste, scrap and rework--and how much overtime is being used on the shopfloor.

Pace Boards were originally developed in Japan over 20 years ago as a way for companies like Toyota Motor Corporation (TMC) and Honda Motor Co Ltd (HMC) to improve their manufacturing processes by reducing waste while increasing throughput time while keeping costs low.

Digital pacing board

Do You Need a Pacing Board?

You need a pacing board if you want to:

- Improve your production efficiency and reduce downtime. A pacing board will help you monitor your shop floor, spot bottlenecks, and identify problems before they happen. You can then make changes that will keep the process running smoothly without having to stop production or lose valuable time in the process of making adjustments on the fly.

- Be more efficient with resources while increasing profits. A well-timed production schedule is key for maximizing profits in manufacturing environments--but it's not as easy as it sounds! With so many different factors at play (e.g., material availability), keeping track of all these variables can be challenging even for seasoned managers who have been doing this work for years...much less someone new or inexperienced with managing large-scale projects like yours may be feeling overwhelmed by what seems like an endless list of tasks that need completing within tight deadlines before starting any new ones again later next month etcetera ad infinitum ad nauseam until infinity ends which could take longer than expected because infinity doesn't end until...

Simple way to monitor and improve production in the shopfloor

A pacing board is a simple way to monitor and improve production in the shopfloor. It's been around for decades, but it's still one of the most powerful visual management tools available today.

Pacing boards can be used to improve processes, increase efficiency and productivity, and streamline your manufacturing process by providing real-time data on your production line. In addition to being an excellent way to monitor workflow, they also help you identify bottlenecks or other problems so that you can make adjustments before they become major issues.

Digital production in smart devices

Conclusion

A pacing board is a simple way to monitor and improve production in the shopfloor. It can help you identify bottlenecks, measure your progress towards targets and make sure that everything is running smoothly. The key is to keep things simple, so that you don't get bogged down with complicated charts or graphs when all you need is a quick glance at an easy-to-read board! If you want to learn more about how pacing boards work, check out our other blog posts on how they can be used by managers or employees alike.